Program 3: Extract

Increasing extraction efficiency

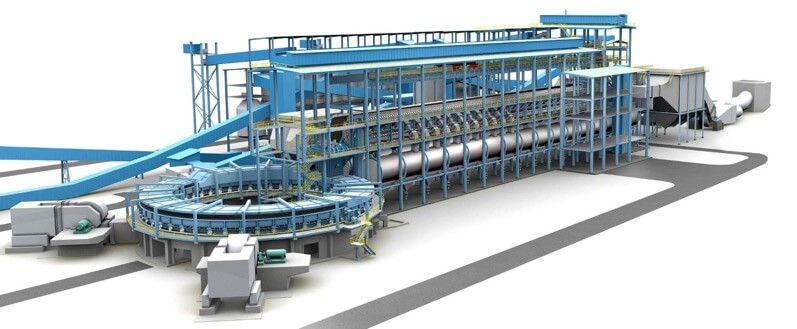

New processing circuit designs, integrated simulation capabilities and operational control systems to exploit changes in grade and other physical properties resulting from Grade Engineered feed streams.

Coarse separation ‘unpacks’ in-situ mineralogy and texture to produce new hybrid streams that can have very different properties to the original material. This includes differences in characteristics such as mineralogy, deleterious phases, particle size distribution and hardness in addition to economic grade. Material can be conditioned using different breakage energies and intensities to enhance or suppress coarse liberation.

The ability to deliver feed material that has already undergone significant coarse liberation and modification prior to traditional processing plants, enables significant changes to current circuit design and operation.

The objective of Program 3 was to develop sophisticated coarse liberation models and operating protocols which could be used as inputs into next generation circuit design and simulation. This included design of new coarse separation circuits in the dig and deliver interface as well as modifications to existing circuits. The ultimate aim was to improve efficiency and productivity across a range of operating metrics such as energy intensity and water consumption in addition to net value.

| Projects |

Project snapshot |

| P3-001: IES Baseline Project | |

| P3-005: AMIRA P420F | |

| P3-006: AMIRA P9Q | |

| P3-007: Validation of mass balance and model calibration in IES (P9Q AR) | |

| P3-008: Comminution optimisation for Grade Engineering | |

| P3-008: Comminution optimisation for Grade Engineering - Close out | |

|

P3-010: Beneficiation of Hard Rock Lithium Ores |

|

| P3-013: Development of gravity-based amenability test for coarse gangue rejection of base metal ores - Close out |

Research milestones

Program 3 built on the successful development of the Integrated Extraction Simulator (IES) in CRC ORE as the enabling tool for simulating and optimising interactions between unit operations. IES is next generation cloud-based enterprise software designed to incorporate new, existing or customized process models and provide a new capability to interact these models across the value-chain. The research objective in Program 3 was to use and develop IES as the enabling software tool to deliver a new approach to Mine Performance Management (MPM) based on emerging Grade Engineering principles structured around system value concepts.

Program 3 built on the successful development of the Integrated Extraction Simulator (IES) in CRC ORE as the enabling tool for simulating and optimising interactions between unit operations. IES is next generation cloud-based enterprise software designed to incorporate new, existing or customized process models and provide a new capability to interact these models across the value-chain. The research objective in Program 3 was to use and develop IES as the enabling software tool to deliver a new approach to Mine Performance Management (MPM) based on emerging Grade Engineering principles structured around system value concepts.

Application of the IES also has the potential to generate novel processing techniques and systems which improve system efficiencies additional to those achieved through enabling grade engineering, and CRC ORE sought such opportunities to extend its field of work where applicable.

Three main research challenges were addressed relevant to delivering a new Mine Performance Management capability based on next generation IES software:

- Developing models for coarse liberation suitable for Grade Engineering from physical properties of feed material

- Developing new unit operation and equipment models which accurately use Grade Engineering inputs to generate performance predictions

- Deploying MPM in a site-based Grade Engineering environment so that the system delivers optimal process improvement.

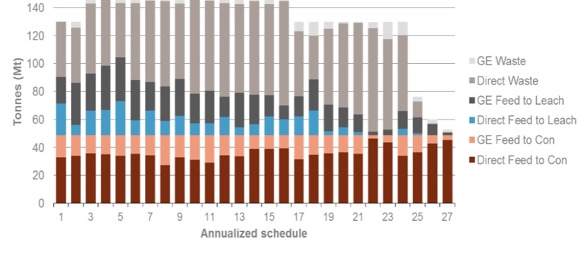

An example of annualised tonnages of material assigned for Grade Engineering® coarse separation compared to overall material movements solved for maximisation of value and fit to operational constraints.

An example of annualised tonnages of material assigned for Grade Engineering® coarse separation compared to overall material movements solved for maximisation of value and fit to operational constraints.