Delivery Themes

CRC ORE had ten Delivery Themes. These packaged the point solutions developed in CRC ORE’s Development Programs, integrating them into a business-facing approach carefully designed to help support the path of new technologies into the business world.

Each theme incorporates a ‘systems thinking’ approach to ensure that the impacts of solutions are assessed across the value chain, improving adoption success rate.

Some businesses will focus on one of these themes, while others will select across a range of the solutions stacks most needed in their business and individual operations.

The themes are dynamic and as new research and technology becomes available, the themes have been designed to seamlessly incorporate into the solutions stack, ensuring that CRC ORE’s innovation pathway remains at the cutting edge.

In close partnership with Participants, CRC ORE utilises value-driven solutions provided by the Delivery Themes to tackle some of the biggest problems facing mining industry productivity.

Each of the Delivery Themes is explained in more detail below.

CRC ORE's Delivery Themes disruptively change the industry’s long-accepted mining and ore treatment paradigms by:

- Exploiting the natural variability of the mineralisation instead of smoothing it out to improve feed grades and net value.

- Treating mining as a fully integrated and value optimised manufacturing business.

- Taking full advantage of the rapidly changing technology, engineering and data landscape to improve productivity and decision making.

GE-enabled block models and mine plan optimisation

GE-enabled block models and mine plan optimisation

CRC ORE has defined five machine-rock ‘levers’ that drive opportunity for coarse separation in the dig and deliver interface prior to traditional processing and recovery.

Understanding and valuing separation opportunity requires new and modified metallurgical-type tests which can provide comparative ranking indices for individual levers capable of population into resource block models. These indices need to be incorporated into mine planning and scheduling to provide alternative options and maximise economic value.

Lack of suitable testing protocols and comparative indices is one reason why the transformational value of Grade Engineering® has not been widely recognised in the industry to this point.

This theme concentrates on providing a suite of innovative laboratory and bulk testing protocols, data analysis and modelling capabilities to generate appropriate coarse separation indices for routine commercial application. The approach is designed to compare results across ore types and operations to recognise and rank highest priority opportunities. In addition to empirical physical testing the theme is also focussed on understanding predictive geological controls which can be used to support spatial interpolation.

Coarse separation indices are dynamic responses involving potential accept/reject yields that can be exploited in different user-defined combinations. This totally changes the concept of fixed in-situ cut-off grades or derived value calculations. To fully understand the disruptive nature and opportunity of exploiting dynamic yields, this theme also involves close collaboration with commercial mine planning and scheduling organisations to deliver maximum value.

Instrumenting the bench

Instrumenting the bench

In large open-pit operations benches prepared for blasting are the last time ore and waste can be characterised and conditioned in-situ.

Improved knowledge at bench-scale informs a large range of downstream decisions, feeds directly into more advanced blast design and enables Grade Engineering® conditioning.

A range of existing or emerging technologies already exist that can provide material characterisation using down-hole, top of hole sensing capabilities for blast hole drilling, or remote scanning of blasted mullock piles. However, despite this availability most technologies have failed to become standard practice in current operations.

This theme focuses on providing new value propositions and integrated protocols for implementing on-bench and in-bench characterisation tools into key decision flows driven by the benefits provided by Grade Engineering®.

The aim is to operate the current dig and deliver interface as a key part of cost-effective mineral processing not simply optimisation of mass material movement. Tracking material after blasting, loading and separation is a key requirement involving next generation smart tagging concepts.

The theme is also looking at narrow diameter directional drilling as a more effective approach for inserting tracking and characterisation devices and networks into the bench outside of current reliance on using large diameter blast holes for physical access.

Sensing and coarse separation in the pit

Sensing and coarse separation in the pit

The net value of coarse separation involved in Grade Engineering® is increased by minimising the number of rehandling steps and operating on the smallest economic ‘minimum separation unit’ possible. The most effective approach is to employ coarse separation as close to the first point of extraction as possible.

This Theme is focused on the design and engineering of mobile in-pit crushing and coarse separation equipment that can deliver maximum benefit. It leverages on engineering work already done on in-pit crushing and conveying solutions but adds significant additional value and modification of purpose. The aim is to provide a mobile in-pit crusher that can operate in full loading automation with a shovel and employ screening and sensing technologies post crushing but before truck loading using surge bins. This would allow high precision drive in drive out truck loading further improving dig and load efficiency to generate additional value.

Separation scale would be at bucket volume (50-150 tons) in the 15-20 second time interval of the dig-discharge shovel cycle. This allows a range of different material presentation geometries to be designed after crushing to improve the efficiency of separation. The aim is a modular design which allows customised separation devices to be installed based on the needs of individual operations and ores. The units would be deployed into those parts of operations with the highest coarse separation opportunity as defined by outcomes of other themes. The result is a combined value proposition based on the benefits of in-pit Grade Engineered stream feeds combined with improved shovel and truck loading productivity.

Delivering grade and throughput engineering

Delivering grade and throughput engineering

Grade Engineering® recognises that the singular industry focus on throughput as a key value driver (i.e. quantity) needs to be matched with a similar focus on maximizing the inherent value of feed (i.e. quality). Optimising feed quantity in the dig and deliver interface is referred to in CRC ORE as Throughput Engineering and incorporates previous initiatives such as Mine to MillTM.

The two approaches operate in same the dig and deliver space and need to be complimentary and synergistic rather than competitive, with optimisation based on maximisation of net value. This requires integration of the two approaches and a clear unbiased focus on using the best combinations of the two options to deliver maximum value. This involves customisation to specific operations and ore types. More effective conditioning through innovative blast design and fragmentation are common to both approaches.

This theme aims to deliver a combined approach as a routine methodology for METS and Miners supported by modelling and simulation tools driven by commercial value propositions.

On-line sensing of coarse streams

On-line sensing of coarse streams

The majority of base and precious metal deposits are heterogeneous in terms of grade and physical properties at a range of scales. This variability can either be blended to produce more uniform feed and product specifications, or exploited to generate higher value batches (e.g. Grade Engineering®). Either approach ideally requires on-line information prior to conventional mineral processing on modified coarse (>10mm) material streams after blasting and primary crushing.

On-line sensing for coarse material streams is much more technically challenging than analysing finer grained material such as flotation feed or slurries. Potential on-line information points include shovel bucket, truck trays and feed conveyors in environments that can include significant problems with material presentation, dust and vibration. While a range of existing and emerging coarse sensor technologies and concepts exist which could deliver this type of information, there is no clear value proposition for what technologies provide the best integrated outcomes and how this would relate to key decisions for specific operations and ore types.

This theme aims to deliver a framework for how this integrated value can be understood and achieved particularly in the transformational context of Grade Engineering®. This includes potential use of surface based versus penetrative sensors and the resolution/decision times involved in generating new value as opposed to information. A key aim is to benchmark and integrate sensing solutions through comprehensive independent field trials. Outcomes will also be linked to amenability testing and block model population.

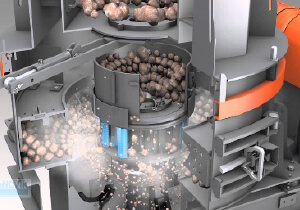

Energy efficient enhanced coarse liberation

Energy efficient enhanced coarse liberation

The propensity of some ores to naturally liberate grade into specific size fractions and mineral association is a powerful lever in Grade Engineering® that can be exploited using screening for cost effective coarse separation. Where this occurs during energy-efficient blasting and primary crushing the outcomes drive significant net value.

The behavior (and benefits) can be further enhanced by conditioning material during blasting and primary crushing to deliver maximum yield. This theme is focused on design and implementation of novel energy-efficient crushing technologies to condition specific ores for enhanced grade recovery, gangue rejection and energy efficiency. These technologies can also radically change the downstream comminution circuit design including direct to ball mill ROM feed options.

The theme will also focus on developing a more fundamental understanding of what controls preferential deportment during initial size reduction leading to a predictive ‘Coarse Liberation Model’ analogous to existing models for flotation-scale liberation and recovery.

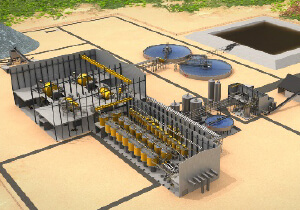

IES-enabled integrated simulation across the value chain

IES-enabled integrated simulation across the value chain

Having user-defined options for manipulating and modifying coarse feed streams requires a new more integrated understanding between resource modelling, mine scheduling, ‘dig and deliver’ material movement, and mineral processing leading to saleable product.

These are traditionally operated as individual unit operations with their own KPI’s, operating cultures and specialist software solutions. Optimising for value across the entire system requires more sophisticated tools which can be used to link key performance models and operational simulations to identify and maximise value-based scenarios.

CRC ORE’s Integrated Extraction Simulator (IES) software is a next generation tool designed to deliver these capabilities. IES is a platform for routinely integrating and interacting existing unit equipment simulations and models that facilitates a new level of predictive simulation and modelling. IES is capable of incorporating industry standard unit operation models, site-specific models or experimental models in user-defined combinations. The power of cloud-based computing provides the ability to run many thousands of interacting simulations in real time to evaluate scenarios and sensitivities across the value chain.

IES can be used to evaluate improvements and sensitivities in current operations or to identify optimal scenarios for implementing improvement initiatives such as Grade Engineering® outcomes. Next generation IES applications also aim to exploit the ever increasing availability of on-line data flows and data historians to self-calibrate operational models and performance.

GE enabled circuit design with advanced process control

GE enabled circuit design with advanced process control

The ability to manipulate new feed streams involving modified grade, particle size distribution and other physical properties using Grade Engineering® concepts, opens up a range of different down-stream processing options to improve overall productivity, energy-efficiency, water balances and recovery.

For existing operations with installed capacity this involves improving overall unit metal productivity, increasing saleable product and reducing unit metal operating costs. For new or expansion operations this can involve improving Capex intensity by reducing capacity needs or radically changing circuit configurations to react to the options provided by modified and customised feed streams. This includes less reliance on energy-inefficient SAG milling, exploiting straight to ball mill ROM options, use of coarse screening to generate intra-mill reject streams, or more widespread use of coarse gravity recovery on conditioned streams.

This theme focusses on new more flexible circuit designs to exploit new feed streams and coarse rejection options to improve operational value. It also is designed to link advanced dynamic mill control with more advanced feed blending options to maximise mill performance. The aim is to exploit the additional benefits of access to customized feed streams generated by coarse separation and on-line coarse feed sensing and data flows through improved and more stable mill or leach performance.

Optimised system value across all operational metrics

Optimised system value across all operational metrics

Managing social licence to operate and competing community claims on consumable resources such as energy, water and environment are increasingly part of understanding full system value. Social metrics need to be optimised and scheduled in the same way as net value, Capex and ROI.

The transformational opportunities offered through Grade Engineering® and associated Delivery Themes also apply to improving key energy, water and environmental metrics as part of overall optimisation.

This theme is designed to ensure that social metrics are built into the overall thinking and capability of CRC ORE’s Delivery portfolio and associated technologies. The aim is to build measures of operating metrics across the value chain so that potential changes in each unit of operation can be interrelated and valued. This will identify opportunities for tracking and improving social metrics as part of a ‘total value’ solution.

Sustaining whole-of-system value

Sustaining whole-of-system value

The global mining industry is not generally regarded as an enthusiastic first adopter of disruptive technology and often operates with a competitive siloed mentality across individual departments. Overcoming this operating culture is a major barrier to entry for disruptive technologies and sustaining the benefits.

Many of the coarse separation technology opportunities offered through Grade Engineering® and other aspects of CRC ORE’s Delivery Themes can be viewed as introducing operational complexity that will generate resistance to site implementation under current operating cultures. The aim of this theme is to identify overarching tools and management systems to counteract this tendency and drive more rapid site acceptance, validation and adoption of technology solutions. This requires a clear focus on value propositions, increased automation of decisions driven by new data flows, and integration into management execution systems (MES) which will react to real-time information on new modified (and disruptive) accept and reject feed streams.

For example, while the capability to optimise material movement in the dig and deliver interface has been transformed by real time data and automation related to fleet management and despatch, there is very limited matching data flows for ‘payload’ quality as a key value driver. Outcomes of the previous Delivery Themes are designed to change this critical lack of knowledge and provide some key user defined options. It is essential that this can be integrated into Integrated Operation Control centres to demonstrate whole of system benefits from adoption. This theme is focussed on partnering with existing commercial groups who can provide ‘whole of system’ optimisation and control functions which can be used to realise and sustain the benefit of CRC ORE’s technology solutions and disruptive benefits. This includes change management and top-down leadership requirements.