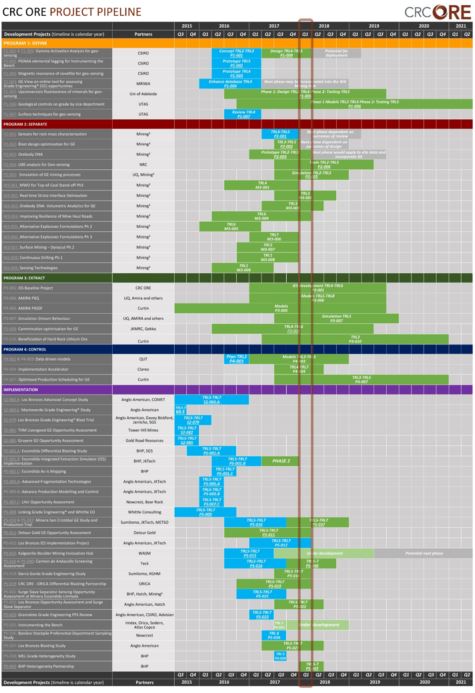

Program 1: Define

Improving feed quality

New and novel testing, measurement and mapping technologies to characterise and quantify waste and ore for coarse separation attributes as inputs into Grade Engineering® assessment and mine planning.

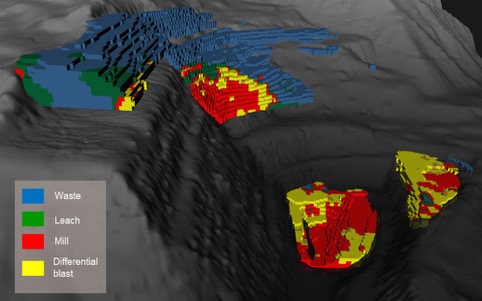

Example of definition of specific domains in a large open pit operation that drive maximum value in a Grade Engineering® assessment – in this case based on application of differential blasting for conditioning grade by size (yellow blocks).Program 1 included predictive performance attributes across the five main rock interface separation levers which drive Grade Engineering® response.

Example of definition of specific domains in a large open pit operation that drive maximum value in a Grade Engineering® assessment – in this case based on application of differential blasting for conditioning grade by size (yellow blocks).Program 1 included predictive performance attributes across the five main rock interface separation levers which drive Grade Engineering® response.

These attributes need to be embedded into spatial models and used to optimise mine planning and scheduling for maximum value.

Coarse separation involves concentration of valuable phases and removal of barren gangue phases in the ‘dig and deliver’ mining interface prior to costly and energy intensive processing.

In current practice attributes required to define and value coarse separation were typically not collected on operations.

Program 1 aimed to provide testing and modelling protocols to populate resource block models with separation attributes that could be used in mine planning and scheduling.

| Projects |

Project snapshot |

| P1-001: Gamma Activation Analysis for geo-sensing - Phase 1 | |

| P1-009: Gamma Activation Analysis for geo-sensing - Phase 2 | |

| P1-002: PGNAA elemental logging for Instrumenting the Bench | |

| P1-003: Magnetic resonance of covellite for geo-sensing | |

| P1-004: GE.View an online tool for assessing Grade Engineering opportunities | |

| P1-005: Upconversion fluorescence of minerals for geo-sensing | |

| P1-006: Geological controls on grade by size deportment | |

| P1-006: Geological controls on grade by size deportment - Close out | |

| P1-007: Surface techniques for geo-sensing | |

|

P1-011: Resource scale heterogeneity evaluation |

|

| P1-013: MR Bench Analysis Stage 1 | |

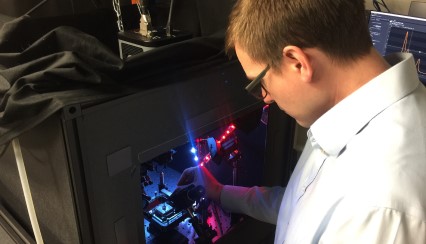

| P1-014: Real-time Fluorine Mineral Identification using Novel Fluorescence Technology | |

| P1-014: Real-time Fluorine Mineral Identification using Novel Fluorescence Technology - Close out | |

| P1-017: Statistical Interpretation of Grade Distribution - Close out | |

| P1-019: MR Bench Analysis Stage 2b - Close out | |

Research milestones

Plan view of contoured blast hole Cu grades for a set of mining benches assigned to mill based on average cut-off grades. Ideally zones shown in green are below mill cut-off grade and represent coarse separation opportunity.

Plan view of contoured blast hole Cu grades for a set of mining benches assigned to mill based on average cut-off grades. Ideally zones shown in green are below mill cut-off grade and represent coarse separation opportunity.

Program 1 aimed to develop a new approach to resource definition to support implementation of Grade Engineering at production scale based around three major challenges:

- A new approach to define and predict spatial domains of heterogeneity in resource definition that can be exploited by Grade Engineering.

- To develop response curves to relate domain heterogeneity to sensor responses and coarse separation opportunities.

- To provide on-line sensor-based telemetry to inform Grade Engineering decisions and operation.

The outcomes included methods to identify and rank productivity improvements between mining projects and ore domains. Predictive indexes on-line measurement options for coarse separation were developed, to allow optimisation and delivery of increased value via Programs 1, 2 and 3.

Comparative ranking of average preferential grade by size Response Rankings for selected deposits. Whiskers show 25th and 75th percentiles

Comparative ranking of average preferential grade by size Response Rankings for selected deposits. Whiskers show 25th and 75th percentiles