Program 2: Separate

Enabling mass separation

Integration of operational strategies and engineering solutions to effect coarse separation in the dig and deliver interface. Projects focused on ensuring that approaches were optimised for net value.

This included advanced blasting design and fragmentation controls; bench scale down hole and top of hole sensors; screening for grade by size conditioned run of mine material; and on-line sensors for coarse material flows at shovel, truck and conveyor belt scales.

The aim was to generate new higher-grade feed streams through physical removal of low value components at coarse (10-1000 mm) particle size distributions after blasting and primary crushing.

The ultimate aim is to undertake coarse separation in-pit as part of dynamic short-term mine planning. This involved design of radical in pit crushing and separation equipment that could also improve digging and loading efficiencies.

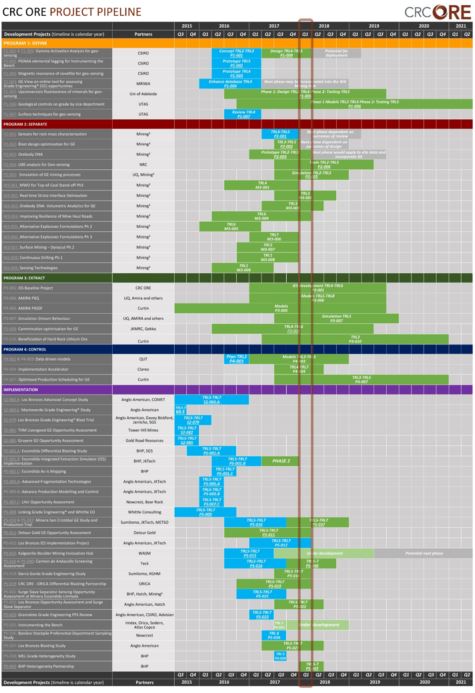

| Projects |

Project snapshot |

| P2-001: Sensors for rock mass characterisation | |

| P2-002: Blast design optimisation for Grade Engineering | |

| P2-003: Orebody DNA | |

| P2-004: LIBS analysis for Geo-sensing | |

| P2-004: LIBS analysis for Geo-sensing - Close out | |

| P2-005: Simulation of Grade Engineering mining processes | |

| P2-006: Mineralogical Characterisation in a Cross-Belt Scanning Setting using LIBS Technology | |

| P2-007: Custom Blast Design Value Proposition | |

| P2-008: Heterogeneity Index for Ore Mixing | |

| P2-009: Elastic Limit Blast Design to Maximise the Grade Engineering Response - Close out |

|

| P2-010: Valorisation of Grade Engineering by-products | |

| P2-010: Valorisation of Grade Engineering by-products - Close out |

|

| P2-011: Alternative Size Separator - Close out |

|

| P2-012: GE Sim Extension | |

| P2-012: Value Model for use of GE Simulation Software - Close out |

|

| P2-013: DAS for non-tumbling ore mills |

Research milestones

Program 2 aimed to implement and optimise coarse separation as an integral part of mass mining to enable Grade Engineering. This involved deployment and validation of new and improved coarse separation technologies including blast conditioning; screening, sensing and gravity; and integrating this into efficient equipment utilisation. The aim was to maintain the cost benefits of high volume material movement while introducing an emphasis on active manipulation of payload quality.

Program 2 aimed to implement and optimise coarse separation as an integral part of mass mining to enable Grade Engineering. This involved deployment and validation of new and improved coarse separation technologies including blast conditioning; screening, sensing and gravity; and integrating this into efficient equipment utilisation. The aim was to maintain the cost benefits of high volume material movement while introducing an emphasis on active manipulation of payload quality.

Several important technical and commercial barriers had to be overcome to achieve these aims. The three main challenges were:

- Validation of suitable sensors for deployment on conveyor belts, capable of informing reliable grade-based separation decisions and defining the resulting value proposition for specific operations and ore types.

- Modification/redesign of current IPCC systems to accommodate bulk screening and sensor-based separation of feed streams to create a new value proposition. This involved close integration with Program 3 to simulate and optimise design of new In-Pit Crushing and Separation (IPCS) systems.

- Blasting is a key energy-efficient material conditioning process to drive coarse separation and Grade Engineering outcomes. Potential benefits of differential blast design were demonstrated in the first term of CRC ORE, but site deployment and validation was necessary to support routine adoption.

Addressing these challenges required close collaboration with METS companies and end-users to exploit, integrate and in many cases modify existing systems for new purpose.